Technical Advantages and Application Scenarios of Low Resistance Aluminum Resistors

Aluminum Resistors

Introduction to Low Resistance Aluminum Resistors

In today's rapidly evolving electronic environment, finding reliable components that can withstand high power demands while maintaining performance is vital. Low resistance aluminum resistors are gaining attention for their numerous advantages in various applications.

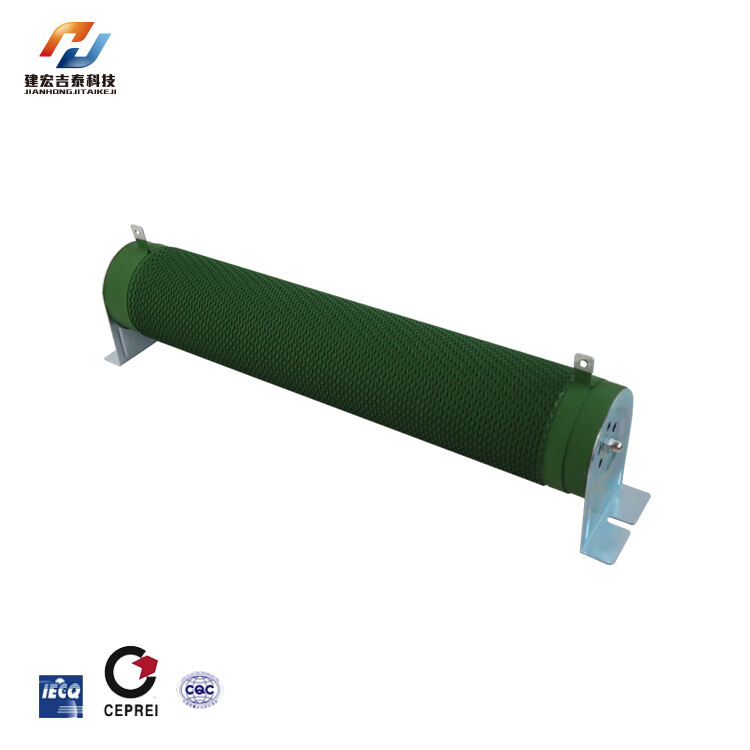

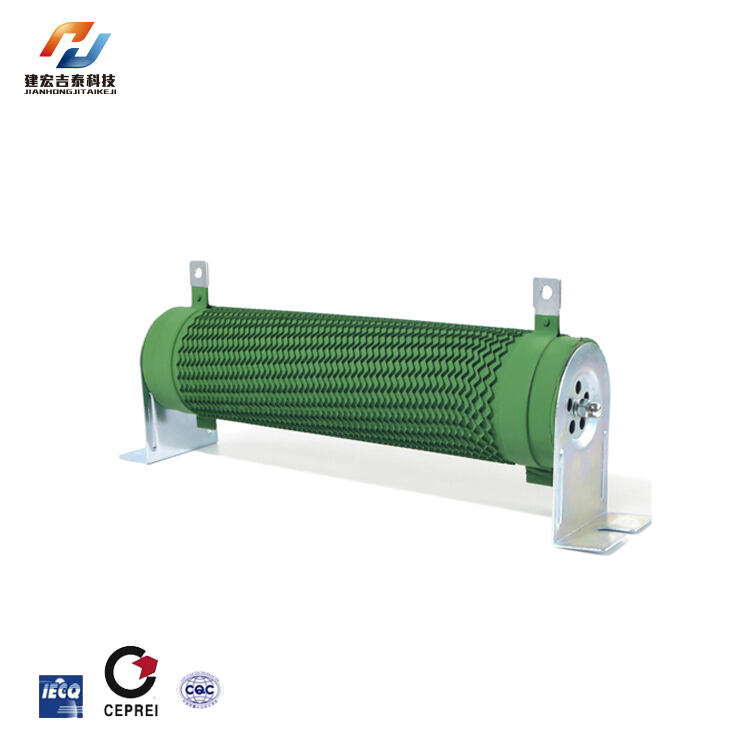

What are Aluminum Resistors?

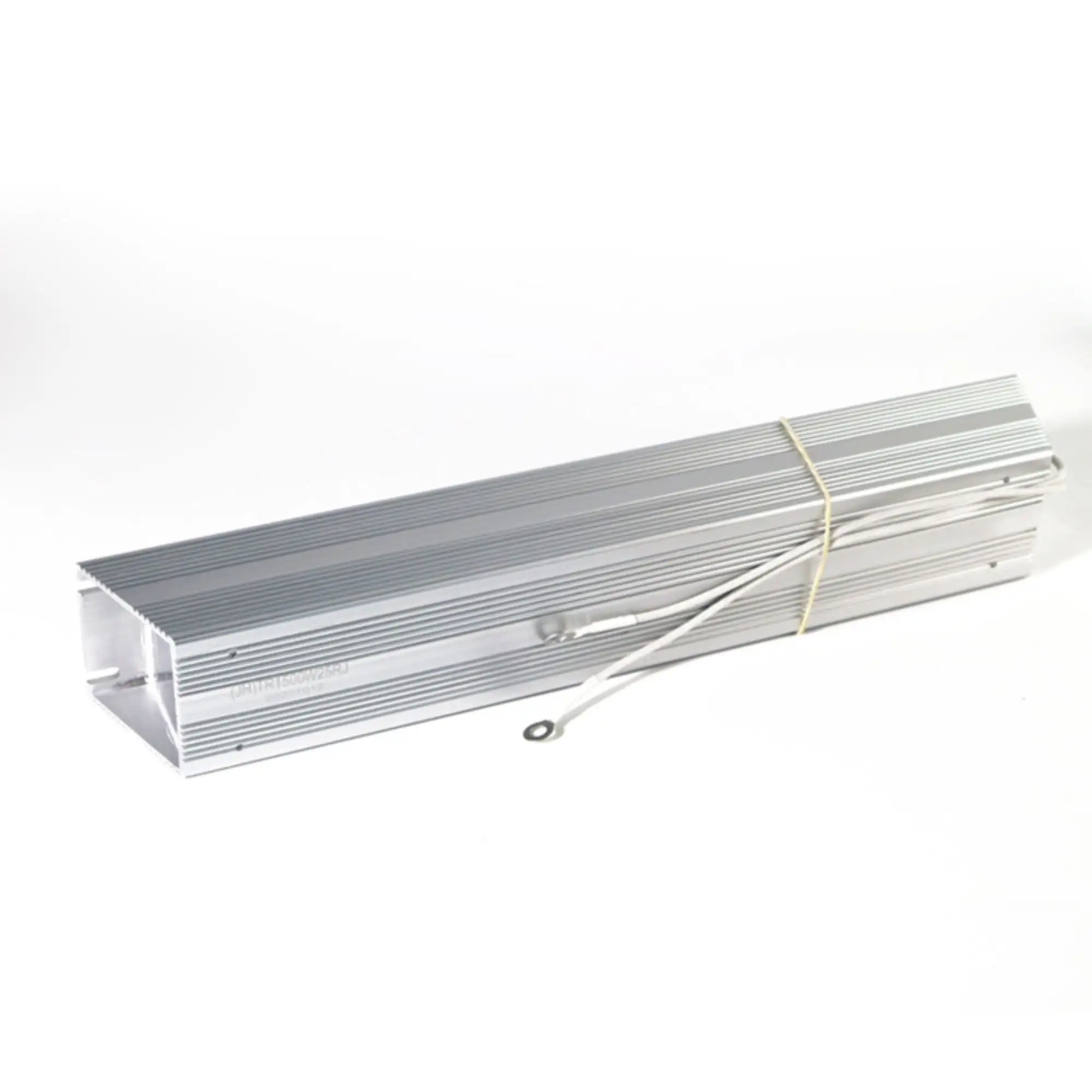

Aluminum resistors are wirewound resistive components insulated in an aluminum housing. This type of resistor is specifically designed to withstand high power applications, offering excellent thermal management due to the aluminum’s natural heat dissipation properties.

Understanding Low Resistance in Aluminum Resistors

Low resistance refers to the resistor’s ability to conduct electricity with minimal opposition. This characteristic is crucial for high power applications where efficient energy transfer is needed, as increased resistance can lead to higher heat generation and potential equipment failures.

Key Technical Advantages of Low Resistance Aluminum Resistors

Understanding the advantages of low resistance aluminum resistors can aid designers and engineers in making informed decisions regarding component selection for their design projects.

Superior Heat Dissipation Capabilities

One of the most significant benefits of aluminum resistors is their ability to dissipate heat efficiently. The aluminum casing acts as a heat sink, which significantly cools the internal components, preventing overheating. This is particularly beneficial in power-critical applications such as electric vehicles (EVs) and industrial automation systems.

High Power Handling and Compact Design

These resistors can handle high power levels (often several kilowatts) while maintaining a compact design. This attribute becomes critical in applications where space is at a premium, such as in automotive and portable devices. By reducing the footprint of high-wattage components, designers can enhance overall system efficiency without compromising performance.

Durability and Resistance to Environmental Factors

Low resistance aluminum resistors are built with durable aluminum alloy materials that are resistant to various environmental factors, such as moisture and corrosion. This durability enables them to operate in demanding industrial settings, ensuring long-term reliability.

Comparison with Other Types of Resistors

To fully appreciate the benefits of low resistance aluminum resistors, it's essential to compare them with other resistor types commonly found in the industry.

Aluminum Housed vs. Cement Resistors

While cement resistors are often less expensive and suitable for lighter applications, aluminum housed resistors offer superior heat dissipation and are better suited for high-power applications. Aluminum housed resistors can withstand higher power loads and are less susceptible to overheating issues, which can lead to component failures.

Inductive Properties of Wire Wound Resistors

Wire wound resistors, including aluminum types, exhibit some inductive properties due to the nature of their construction. This characteristic is beneficial in low-frequency applications, but care should be taken when using them in high-frequency circuits. Non-inductive winding techniques can be employed to minimize unwanted inductance.

Thermal Performance in Different Applications

Aluminum resistors outperform cement resistors in thermal performance when subjected to high energy environments. Applications such as braking resistors in variable frequency drives utilize aluminum resistors due to their ability to handle rapid thermal cycling effectively.

Application Scenarios of Low Resistance Aluminum Resistors

Low resistance aluminum resistors have found a multitude of applications across various sectors, showcasing their versatility and efficiency.

Use in Power Electronics

High-performance power electronics systems incorporate these resistors within power supplies, inverters, and transformers, where their heat dissipation and robustness offer longer operational lifetimes and enhanced safety.

Applications in Electric Mobility

These resistors play a crucial role in electric vehicles. They help dissipate energy during regenerative braking and manage the heat produced during high current applications, ensuring systems function reliably under varying conditions.

Industrial Automation and Control Systems

In industrial settings, aluminum resistors are utilized within automation controls and variable speed drives. Their rugged design and ability to manage heat effectively make them an ideal fit for sectors that demand both reliability and performance in challenging environments.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ