Role of Power Wirewound Resistors in Industrial Control

Role of Power Wirewound Resistors in Industrial Control

In the modern industrial landscape, electrical components play an essential role in the functionality and reliability of machinery and equipment. One such critical component is the power wirewound resistor, renowned for its high precision and robust performance.

Understanding Power Wirewound Resistors

Definition and Construction

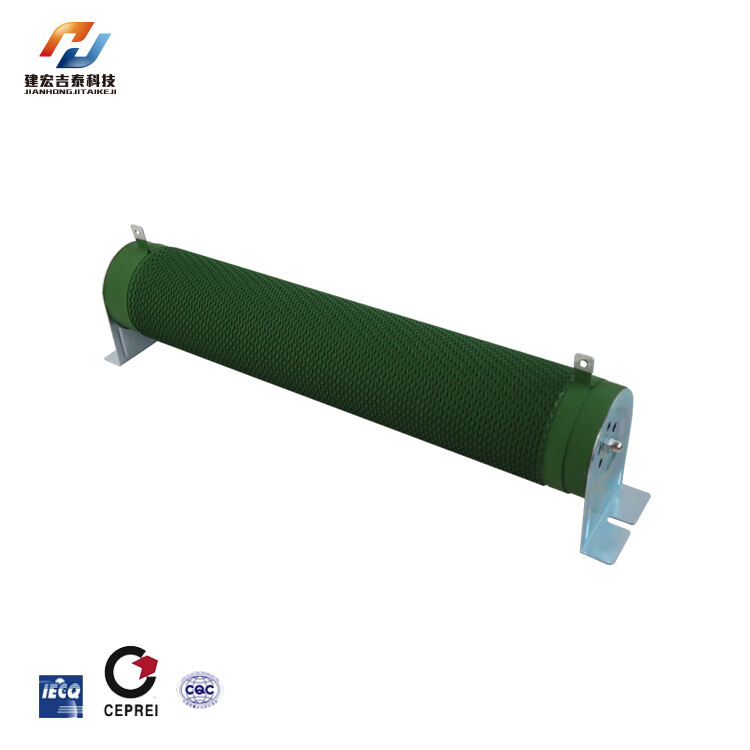

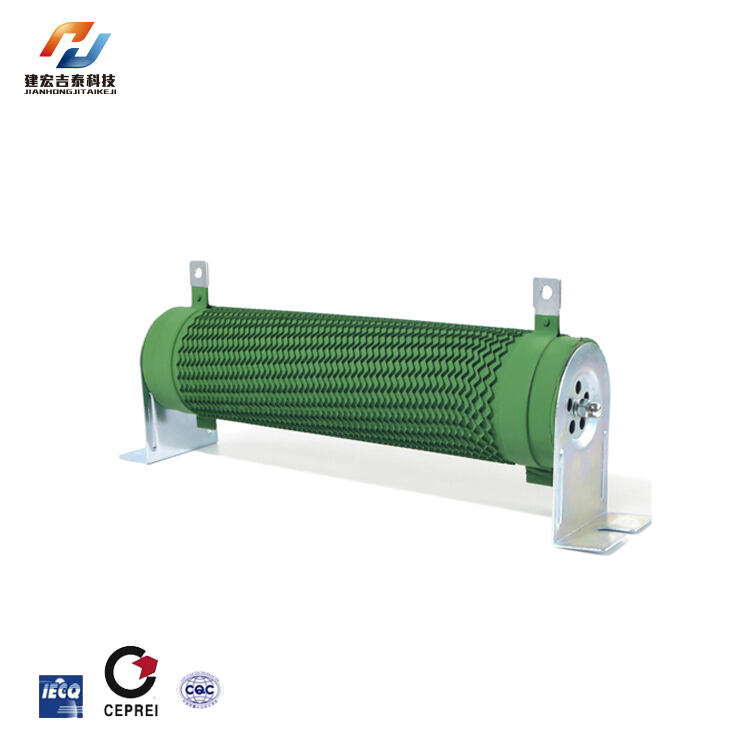

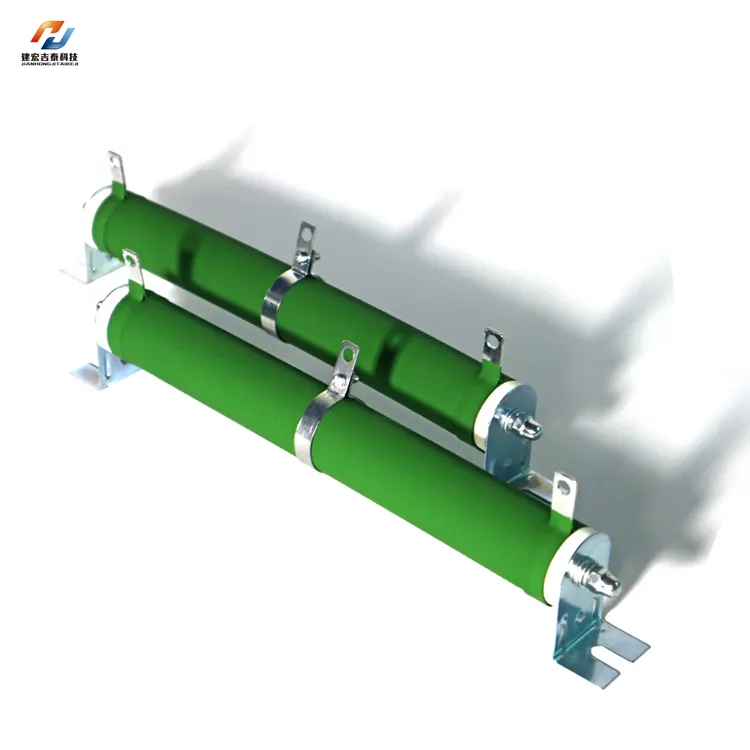

Power wirewound resistors are passive electrical components that manage current flow within electronic circuits. They are made by winding a metal wire—typically nichrome or manganin—around an insulating core, usually ceramic or fiberglass. This configuration allows them to handle substantial power levels while dissipating heat effectively.

The resistive wire is complemented by protective coatings, such as vitreous enamel, that enhance durability and thermal stability, making them operable under high-temperature conditions.

Key Materials Used

The functionality of power wirewound resistors is significantly influenced by the materials used in their construction:

Resistive Wire: Commonly made from high-resistance alloys like nichrome, offering excellent heat resistance and stability.

Core Materials: Ceramic or fiberglass is preferred for their insulating properties and ability to withstand high temperatures.

Coating Materials: Vitreous enamel is often employed to protect the resistor from environmental factors.

Working Principle

The functioning of these resistors is based on Ohm's Law, which relates voltage, current, and resistance. The wound wire effectively converts electric energy into heat through its resistance, allowing it to limit current flow within a circuit without failure. Wirewound resistors maintain stable performance even under fluctuating temperatures, making them a reliable choice in industrial applications.

Types of Power Wirewound Resistors

General Purpose Wirewound Resistors

These versatile resistors cater to a broad spectrum of applications, providing a stable performance at a relatively low cost.

Precision Wirewound Resistors

Designed for applications requiring high accuracy, these resistors operate with tight tolerances significantly improving measurement reliability.

Safety Wirewound Resistors

These incorporate flame retardant coatings that prevent overheating, ensuring safe operation and extending operational life.

Fusible Wirewound Resistors

Fusible designs offer self-protecting features; they burn out under excess load without production of flames, providing a safer alternative for circuit protection.

Pulse Wirewound Resistors

Specially designed to handle short-duration impulse events, these resistors can withstand power surges, making them ideal for applications where momentary high energy is commonplace.

Applications in Industrial Control

Role in Power Electronics

Power wirewound resistors are prevalent in power electronics, specifically in voltage regulation and power conversion. They dissipate heat generated by high currents, ensuring the reliability of power supplies and motor drives.

In Motor Controls

These resistors are fundamental in motor control applications, where they help manage the start and stop phases while facilitating effective energy management.

Temperature Sensing Applications

Wirewound resistors also find a niche in temperature sensing systems. Their stability and low temperature coefficients make them ideal for accurate thermometric measurements and control processes.

Advantages of Power Wirewound Resistors

High Power Handling Capability

Their robust design allows wirewound resistors to handle high power levels, crucial for industrial equipment that operates under strenuous conditions.

Precision and Stability

Wirewound resistors provide high precision with low temperature coefficients, ensuring that resistance values remain stable across a range of operating conditions—a must-have for applications requiring accuracy.

Low Temperature Coefficients

Their low temperature coefficients signify minimal resistance drift, enabling consistent performance in circuits subjected to varying temperature conditions.

Considerations for Selecting Power Wirewound Resistors

Resistance Values and Tolerance Levels

It is essential to select a resistor whose resistance value aligns with the application requirements to prevent circuit inefficiencies.

Power Ratings and Heat Management

Evaluating power ratings is critical since exceeding these limits can lead to overheating. Proper heat management—often through heatsinks or appropriate mounting—is essential.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ