Understanding Porcelain Tube Winding Resistance In Electrical

Without doubt, porcelain tube winding resistance is a vital factor in electrical applications, especially in high-voltage systems where dependability and effectiveness of power transmission is highly valued. For over a century, porcelain has been the preferred insulator material in electrical equipment because of its excellent dielectric properties and thermal shock resistance. Nonetheless, the overall performance of the system can be greatly influenced by the resistance offered by conductor windings around these porcelain tubes.

Factors Affecting Porcelain Tube Winding Resistance

Several aspects such as wire or conductor type, tightness of winding, tube diameter and number of turns contribute to resistance in a porcelain tube winding. The conductor material is very important because different metals have different resistivities. Copper and aluminum are commonly used because they have low resistivity although the choice depends on the specific application.

Resistance is also affected by how tightly wound the coil is. In case of movement or friction over time this may result in increased resistance and possible points of failure. Conversely, an extremely tight winding can subject the conductor and porcelain tube to stress that may cause cracking or other forms of damage with time.

Tube diameter also matters for consideration. By decreasing proximity effect a larger diameter allows more space between turns thereby reducing overall resistance. However, this has to be weighed against physical size constraints imposed by application.

Also significant, however, is the number of turns which directly impact total resistance. More turns imply more resistant length within the winding therefore enhancing R=kL/A where L stands for length and A cross-sectional area respectively. Designers must weigh this against required inductance and resistance for optimum operation of systems.

Strategies for Optimization

There are several strategies engineers can use when dealing with porcelain tube winding resistance effectively: use highly conductive materials while using advanced coating technologies to reduce surface wire resistivity; employ precision manufacturing techniques that ensure tightness of the winding remains consistent and optimum.

Finite element analysis (FEA) can assist engineers in optimizing designs so that the effects of different parameters on resistance can be modelled and analysed, leading to informed decisions made during design. In addition, machine winders provide uniformity and precision through automation, reducing possible variability and defects that may increase resistance.

Understanding and managing porcelain tube winding resistance is vital for ensuring reliable and efficient electrical systems. Engineers can develop components with excellent performance characteristics that minimize energy losses by considering factors affecting resistance and applying strategies for optimization. These are the critical components we shall consistently refine as technology advances possibilities in electrical engineering.

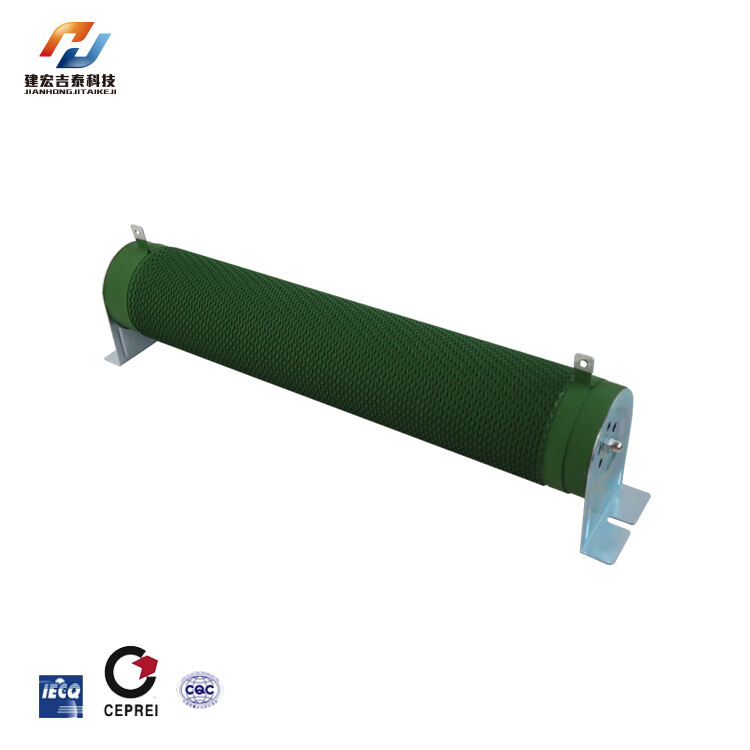

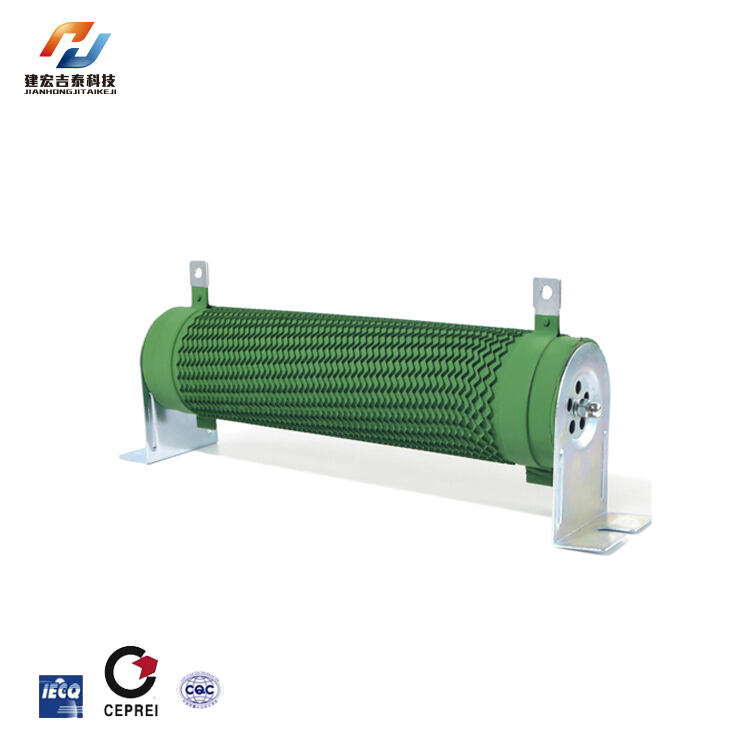

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ