Understanding Porcelain Tube Winding Resistance: A Comprehensive Overview

In the field of electrical engineering and materials science, the ability of porcelain tube winding resistance to work is a critical parameter. For different electrical applications, this resistance measurement is very important in determining the performance and reliability of component insulated with porcelain.

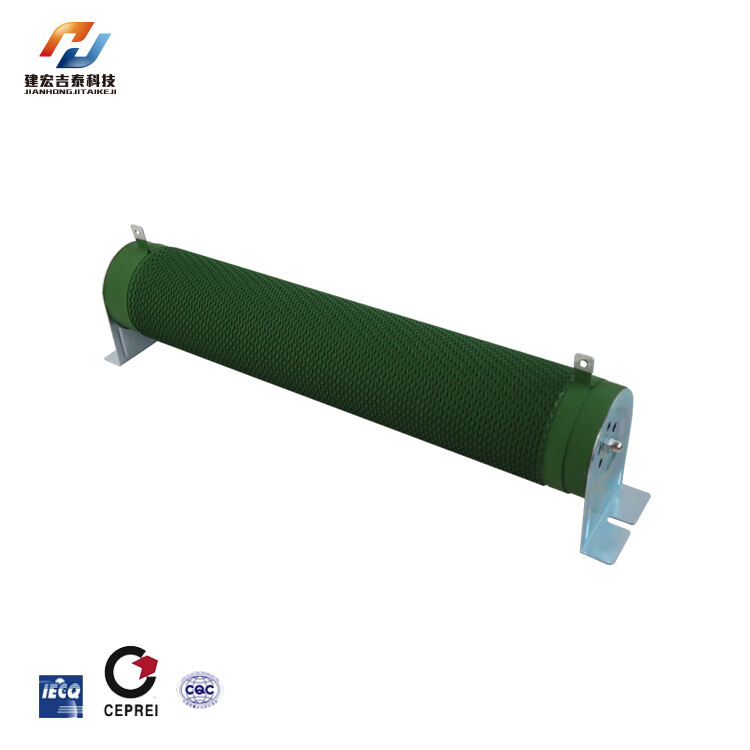

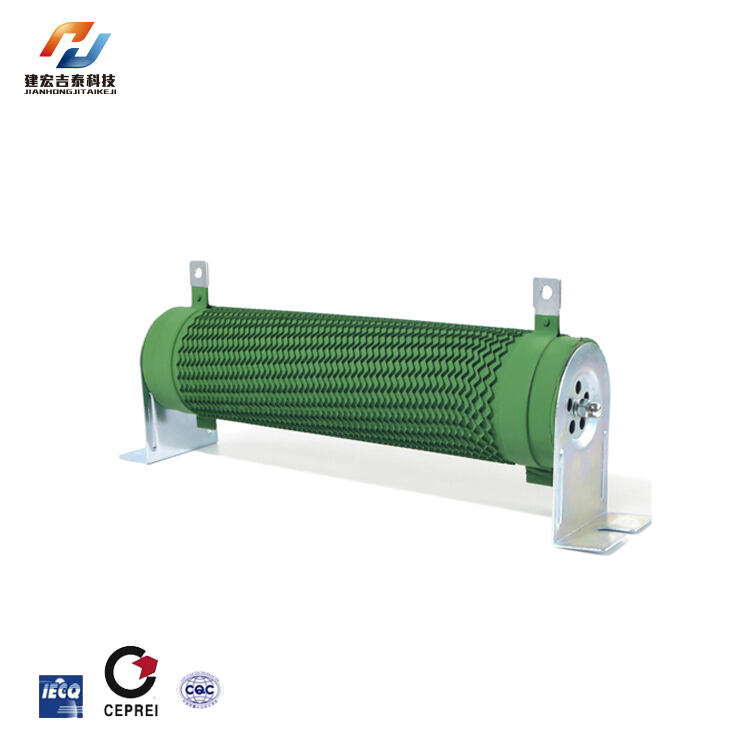

What is Porcelain Tube Winding Resistance?

Porcelain tube winding resistance refers to the electrical resistance encountered in the winding of components that use porcelains tubes for insulation. Electrical equipment like transformers, capacitors and insulators generally use porcelain as it has high dielectric strength coupled with durability. The efficiency, safety and life span of these electric systems can be influenced by windings’ resistances.

Importance of Measuring Porcelain Tube Winding Resistance

Performance Evaluation: Evaluating how well an electrical component performs requires accurate measurements of its porcelain tube winding resistance. High values of resistance imply good insulation, which is essential for avoiding energy wastage and maintaining effective operation.

Safety Assurance: By measuring winding resistance electrical systems have their safety assessed. Proper insulation prevents short circuits as well as any other electrical faults hence reducing risks from damages or accidents happening through them.

Longevity and Reliability: Components with the best winding resistance in porcelain tubes suffer less decay or malfunctioning. Regularly checking resistance can predict possible issues and prolong equipment life.

Measurement Techniques

Ohmmeter Method: An ohmmeter is commonly used to measure the winding resistance of porcelain-insulated components. This device applies a known voltage and measures the resulting current to calculate resistance.

Insulation Resistance Tester: This special tool measures the resistivity of dielectric material inside porcelain tubes which determines their ability to withstand electric leakage by applying high voltages.

Continuity Tester: A continuity tester may be used for simple applications where it ensures that there is proper connection and insulation within the windings of porcelain tube.

Impact on Electrical Systems

Efficiency: Proper porcelain tube winding resistance prevents energy loss from an electrical system, thus optimizing its operation. Low resistance in the winding means less power dissipation and greater efficiency.

Heat Management: If there is not enough resistance, excess heat will be generated thereby causing thermal degradation of elements involved; while accurate measurement allows appropriate control over heat levels needed for maintenance purposes

System Stability: Stable porcelain tube winding resistance contributes to the overall stability of the electrical system. This is because it prevents fluctuations and maintains reliable performance.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ