Understanding Porcelain Tube Winding Resistance

Introduction to Porcelain Tube Winding Resistance

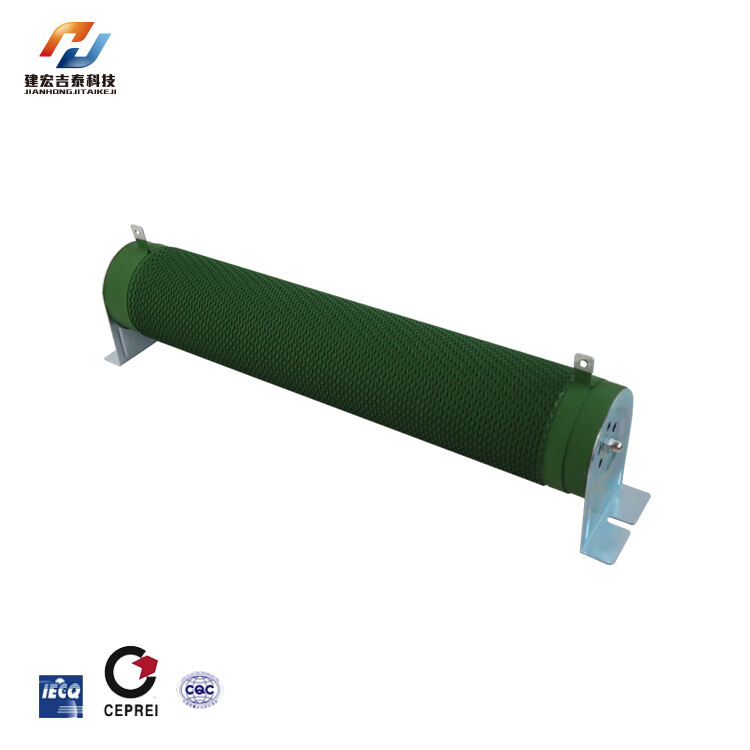

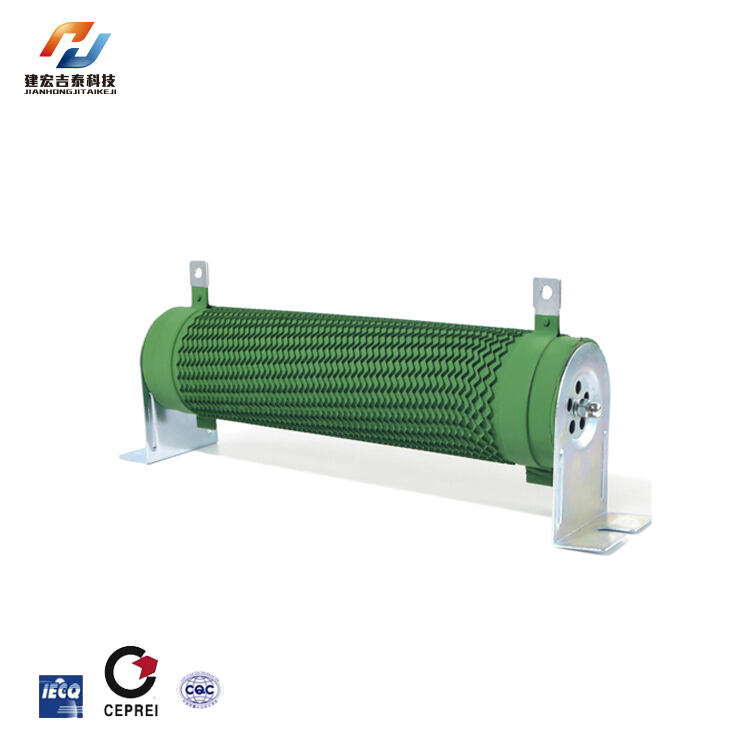

Porcelain tube winding resistance is an essential part in many electrical systems, which is made up of a wire that wound around the form (usually made of porcelain) with a high electric resistance and insulation. This type of resistor is used to have control over electricity flow accurately such as in power tools, electronic devices and in industrial machinery. In the article, we will discuss about the characteristics, uses and manufacturing process of porcelain tube windings.

Unique Properties of Porcelain Tube Winding Resistors

Using porcelain as the material for tubes provides some benefits. Porcelain can resist breaking down when high voltages are applied because it has good dielectric strength. It also withstands thermal shock and chemical corrosion thus making it ideal for use in harsh environments. Because it is hardy, porcelain is suitable for heavy applications that require stability.

Applications of Porcelain Tube Winding Resistors

These types of resistors find great utility in telecommunications; where they ensure signal transmission regulation takes place on smoothly. For sensitive diagnostic equipment requiring precise electrical regulation, they are essential components used in medical field. They are additionally employed in consumer electronics aimed at maintaining stable performance and a long life.

The toughness of these types makes them appropriate for use under extreme conditions experienced by military or aerospace applications. There should be no failures within such systems simply because they cannot afford any.

Manufacturing and Quality Control

Porcelain tube winding resistors production involves attention to detail and precision. Our company Jianhong Jitai applies advanced skills that allow us to evenly wind resistant wires all over porcelain tubes keeping their resistance values same always. To ensure each resistor meets our quality standards there are stringent checks during various stages of production.

Innovations in Porcelain Tube Winding Technology

Just like technology changes so does the development process taking place with other types including those made from ceramic materials. Researchers are looking into using new materials and designs to improve their performance and make them smaller without reducing how long they last or efficiency. As an example, nanotechnologies are currently used in producing resistive coatings that do not wear out easily thus prolonging the life of these resistors.

Future Outlook for Porcelain Tube Winding Resistors

In future, porcelain tube winding resistors will be in high demand as part of emerging technologies such as electric cars and renewable energy systems. It is their ability to perform under difficult conditions that make them preferable to designers and engineers who strive to innovate.

Conclusion: Porcelain Tube Winding Resistors – A Trusted Solution for Exacting Applications

To sum up, porcelain tube winding resistors act as a key component for exact control over electrical currents across various sectors. This unique blend of insulation features, durability and performance makes it essential for modern electrical system components. Even with our continuous improvement in quality at Jianhong Jitai, we are determined to remain the industry leaders in production of porcelain tube windings suitable for current technological needs.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ