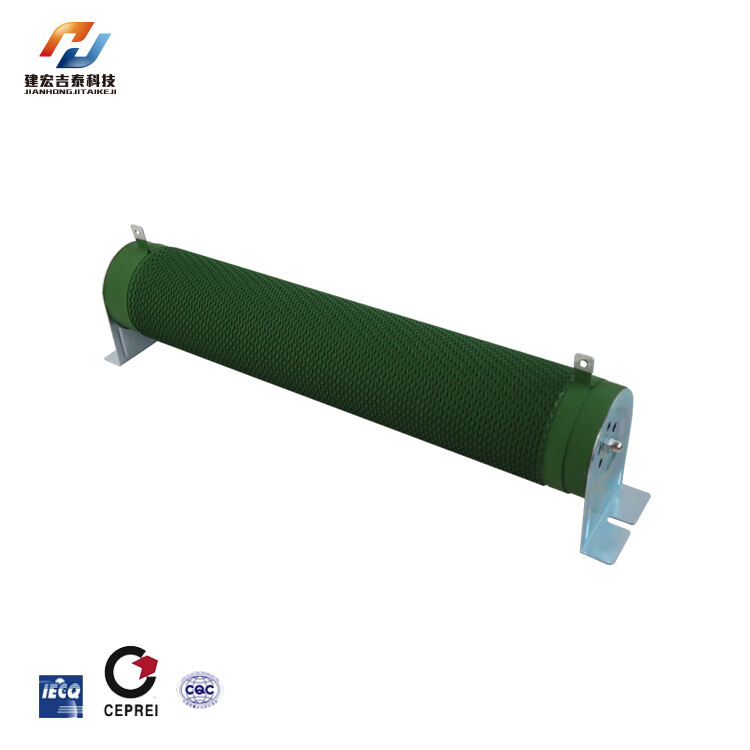

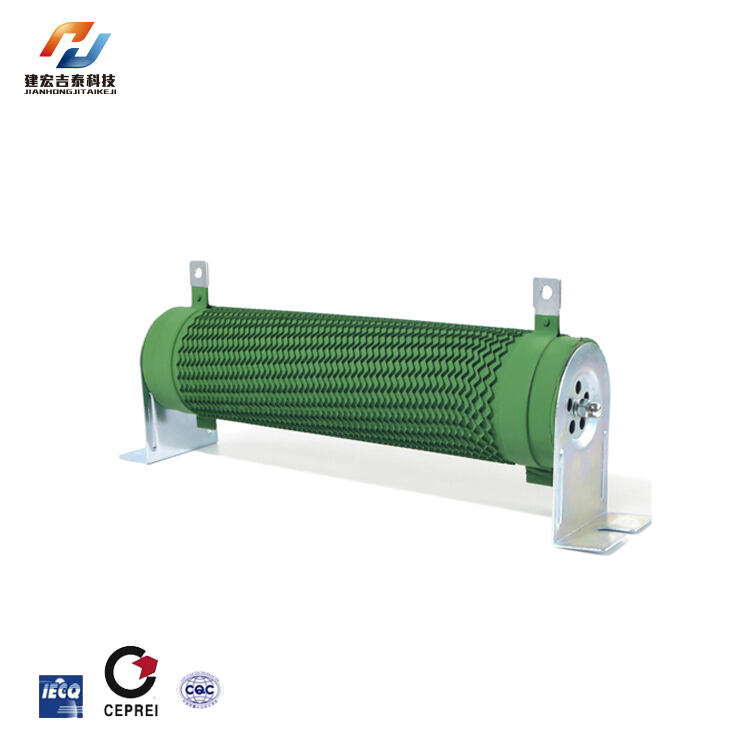

Porcelain Tube Winding Resistance in Electronic Applications

In the rapidly changing world of electronics, several parts are highly significant in making devices run smoothly. One of these is wirewound resistors, more commonly known as porcelain tube winding resistance that has multiples uses. The significance, features and applications of porcelain tube winding resistance are examined here in.

Significance of Porcelain Tube Winding Resistance

Porcelain tube winding resistance capacitors are a kind of resistor that employ a wire coiled around ceramic core and confined within a porcelain tube. It is designed this way to make it have some advantages such as high stability, good heat diffusion and imperviousness to chemical attack. Consequently porcelain tube winding resistance is often found in places where precision, reliability and durability are paramount.

Characteristics of Porcelain Tube Winding Resistance

The construction and materials used for porcelain tube winding resistance determine its key characteristics. Its stable ceramics cores also allow for good thermal conductivity whereas enclosing them with porcelain tubes shields them from other environmental factors. In fact even the wire wound element itself is made from best quality materials hence it has long term stability together with precise resistance values.

Resistance values can scale up to several megohms depending on the specific application for which they were designed. This wide range of values allows design flexibility thereby accommodating various electronic circuits’ requirements.

Applications of Porcelain Tube Winding Resistance

Because it possesses excellent properties, porcelain tube winding resistance has numerous applications in different fields. It finds use widely in power electronics like motor control circuits, inverters and other related high power applications. These systems operate under demanding conditions hence the need for high stability as well as reliability.

It is also used in measuring/control circuits within precision instrumentation; its low temperature coefficient combined with accurate measurements.

Finally, medical electronics aerospace among others uses devices made out of procelian tubing windings resistances since they rely on precise functioning equipment which could be fatal if failed.

In conclusion, porcelain tube winding resistance is an essential component in electronic applications. It is designed so that it has good heat dissipation, stability and resistance to chemical attack due to its unique construction and materials. Therefore where power electronics, precision instrumentation, medical electronics, or aerospace are concerned it tends to be used for a wide array of purposes as mentioned. Porcelain tube winding resistance continues to be very important in ensuring the smooth operation of electronic devices; because of its reliable performance together with precise resistance values.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ