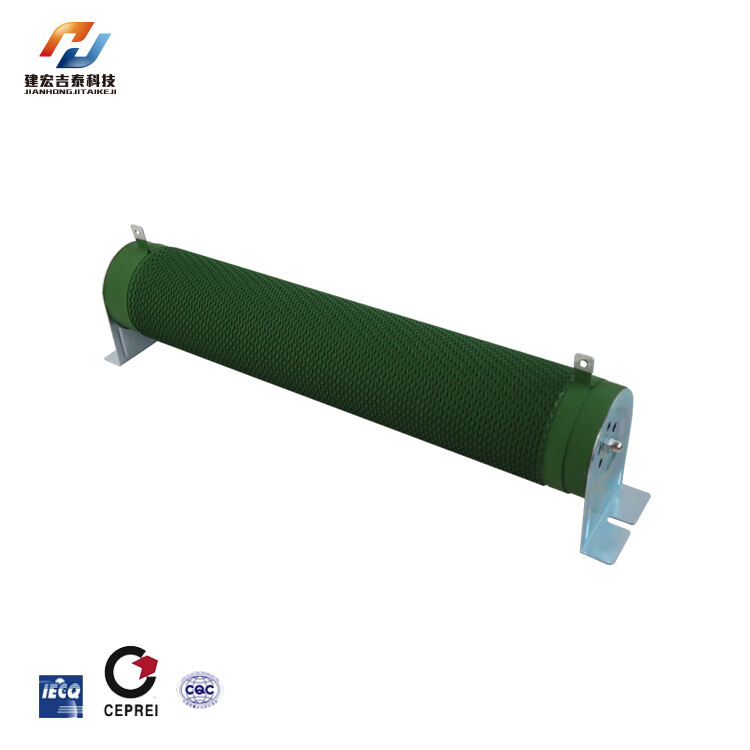

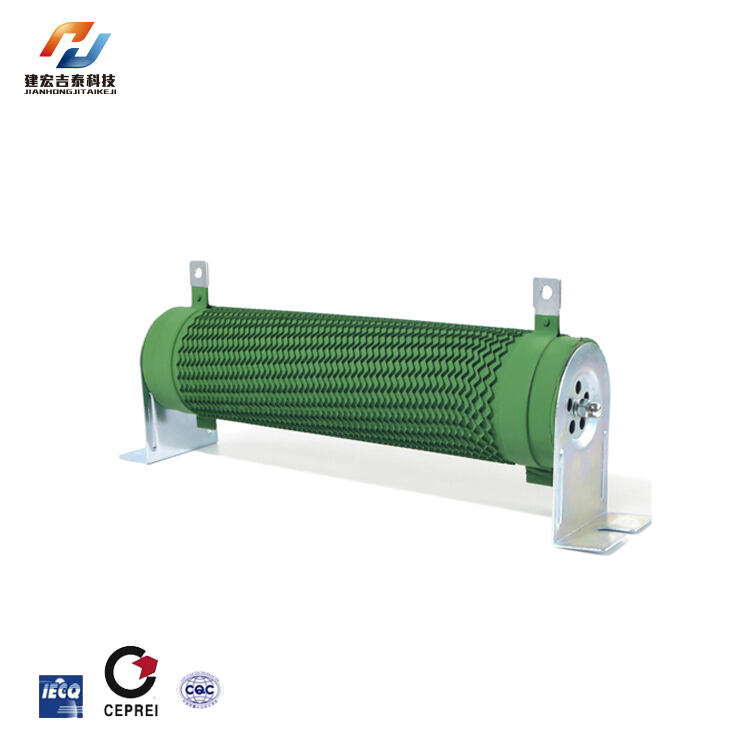

High Precision Aluminum Resistors For High-Quality Electronic

In the field of electronics, precision is key. The high precision aluminum resistor is a fundamental component that guarantees the accuracy and reliability of electronic circuits. They are designed to meet exacting standards as they are indispensable in diverse applications where tight tolerances come into play. This article will deliberate on these resistors’ properties, uses, and the importance of keeping them up for maximum performance.

What Are High Precision Aluminum Resistors?

High precision aluminum resistors are specifically characterized by ultra-low tolerance and temperature coefficient values, which makes them maintain resistance value within very narrow limits over wide range of temperatures. Normally made from high-purity aluminum matrixes then shaped or formed into any desired size or shape. Through their constituent material and production techniques, these resistors offer better performance compared to standard alternatives.

Key Features of High Precision Aluminum Resistors

Low Tolerance: These resistors have tolerances that can go as small as ±0.01%, guaranteeing accurate circuit behavior.

Low Temperature Coefficient (TCR): Their TCRs may be few ppm/°C ensuring suitability for applications affected by heat variations.

Long-Term Stability: As a result, these resistors show little deviation over long periods rendering them reliable during extended services.

High Reliability: Manufactured according to stringent quality criteria, they repeatedly deliver under different stress scenarios.

Applications of High Precision Aluminum Resistors

The application scope for high precision aluminum resistors cuts across various industries and devices:

Industrial Automation: This is required in control systems and sensors demanding accurate signal conditioning.

Measurement and Test Equipment: It’s also used in multimeters, calibrators among other instruments requiring very high accuracy levels.

Communication Equipment: They also find use in base stations and radio equipment where stability is crucial.

Medical Devices: Examples here include monitors among other life-critical devices used for diagnostics purposes.

Maintaining High Precision Aluminum Resistors

Proper maintenance is required to ensure your high precision aluminum resistors continue functioning optimally:

Cleaning: Ensure that no foreign matter is present on the resistors, as these can affect their operation.

Environmental Control: Protect them from extremes of temperature or humidity which could destroy them.

Regular Calibration: This guarantees that they remain within specified tolerances over time.

Proper Handling: No stress or mechanical shock should be imposed on the resistor element leading to its damage.

High precision aluminum resistors are vital components in top-notch electronics’ design. Their ability to maintain resistance values with minimal deviation makes them crucial for applications requiring stringent accuracy. Understanding their features and following appropriate maintenance guidelines will help engineers and do-it-yourself enthusiasts get good results from their electronic projects. These resistors inherently serve as the spine for precision in electronics, thereby ensuring unbeatable performance and durability.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ