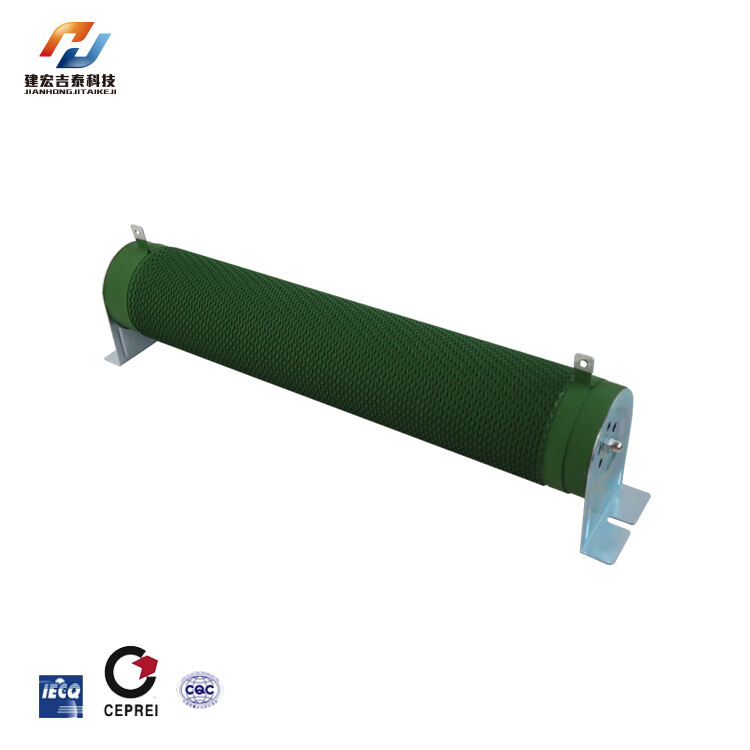

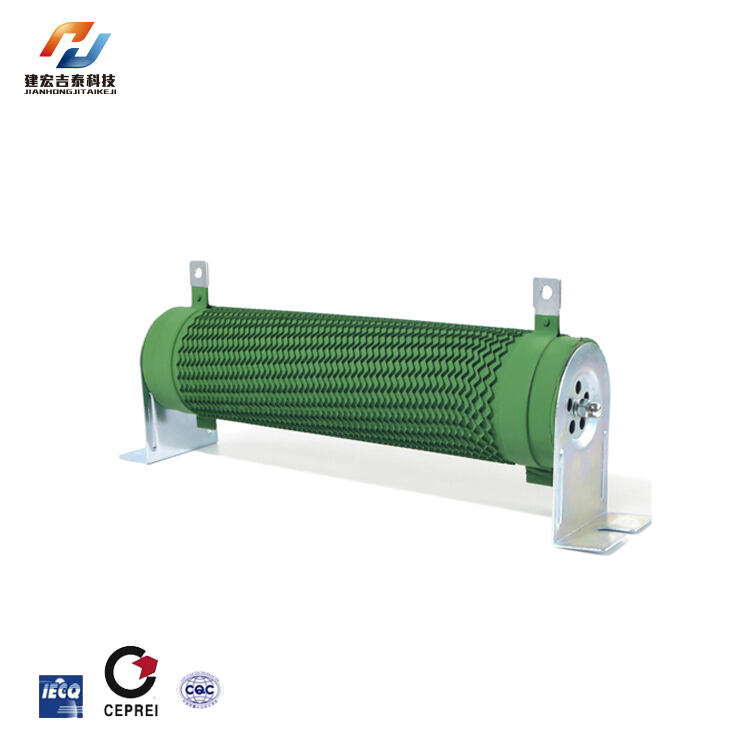

Aluminum Shell Resistors: A Mix of Sturdy and Electrical Functions

Introduction:

In the intricate world of electronics, resistors play a pivotal role in controlling and regulating the current flow. The nature of the internal material used to construct a resistor determines its electrical behavior, but also matters concerning protection and long-term reliability. Among others, aluminum shell resistors are singled out for their combination of robustness, heat dissipation capabilities as well as electrical function.

The Significance of Aluminum Shells:

Aluminum is an excellent choice for making resistor shells because it is lightweight and strong enough. It has high corrosion resistance ability and it is also a good heat conductor; hence shield electronic components from harsh environmental conditions while removing generated heat during resistor operation. Besides, the aluminum shell acts like a casing that withstands the internal elements from being physically damaged and therefore it guarantees their performance stability with time.

Electrical Functionality Uncompromised:

Durability and cooling may be emphasized, but not at the expense of electrical functionality in aluminum shell resistors. To get precise resistance values, an accurate selection or design method should be employed on those made up of higher-resistivity materials like carbon compositions, metal films or wire wound construction types among others. Thus any other quality resistor would result in right regulation of current flow through voltage division across different sections within electric circuits including this aluminum type.

Advantages of Aluminum Shell Resistors:

Durability: The life cycle of these devices can be prolonged due to their moisture-proof and shock-resistant nature that comes as a result of use hardy aluminium outer shells.

Heat Dissipation: Thermal conductance rate by aluminum makes sure that there are no runaway thermal reactions so resistance does not change abruptly either.

Versatility: With multi-size alternatives ranging from various shapes into many resistances possibilities covered; all have some applications over which these items can be conveniently tailored.

Easy Mounting: These parts have got tabs or placement holes within the external housing, simplifying installation into electronic systems.

Applications:

Aluminum shell resistors are used in different industries such as automotive, aerospace, industrial automation, and consumer electronics. They are particularly suited for high-power applications where heat dissipation is a critical factor and environments with severe temperature and humidity conditions.

Conclusion:

In conclusion, aluminum shell resistors combine resistance to heat dissipation, durability and electrical function. The sturdy aluminum container acts as an efficient protector of delicate internal components while at the same time enhancing dissipation of heat. Aluminum shell resistors can be easily mounted due their flexibility and they contribute towards coming up with robust electronic systems by engineers designing these.

Recommended Products

Hot News

-

What Are The Functions Of The Ac Load Box For Power Supply Detection And Maintenance

2024-01-11

-

The Use Characteristics And Methods Of The Load Bank Of The Generator Set

2024-01-11

-

The function of the load bank

2024-01-09

-

Explore The Types And Characteristics Of Resistors: Fixed And Variable Resistors

2024-01-09

-

How Resistors Work And Their Applications In Circuits

2024-01-09

-

Load Banks: Ensuring Optimal Performance in Power Testing Environments

2024-10-21

-

Exploring the Advantages of Wirewound Resistors for Precision Applications

2024-10-14

-

Understanding the Benefits of Aluminum Resistors in High-Performance Applications

2024-10-08

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

LO

LO

LA

LA

NE

NE

MY

MY

UZ

UZ